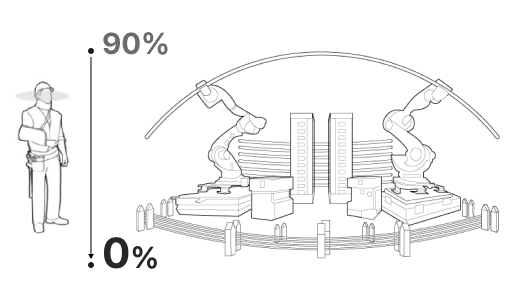

Pre-assembly is a labor-intensive process,

with over 90% relying on manual labor.

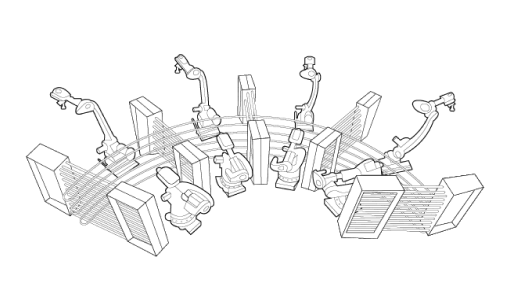

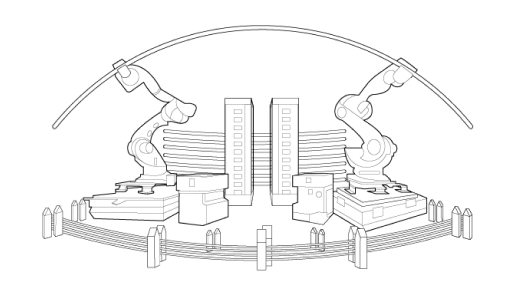

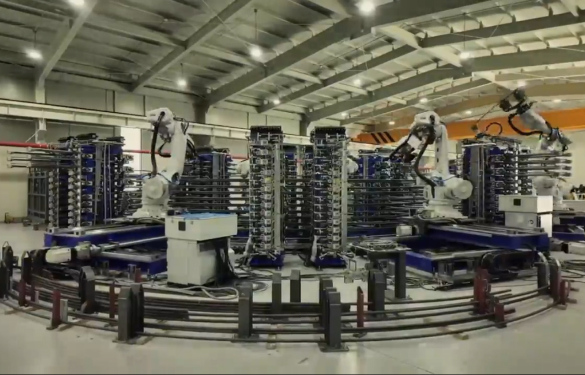

The ANTON solution enables unmanned production through

robotics-based automation.

The ANTON solution, powered by robotics, is optimized for

handling and loading heavy rebar, a task challenging for

human operators.

It Achieves 5-10 times the productivity of traditional manual

operations (based on PC Arch 6-ton segment production).

* Production Standard for PC Arch 6-Ton Segment"

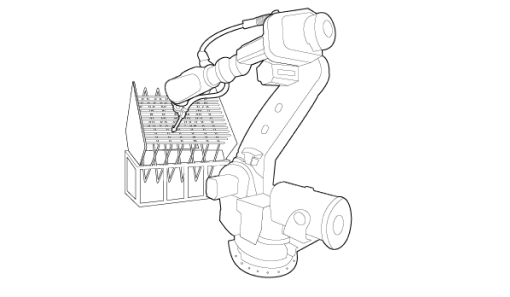

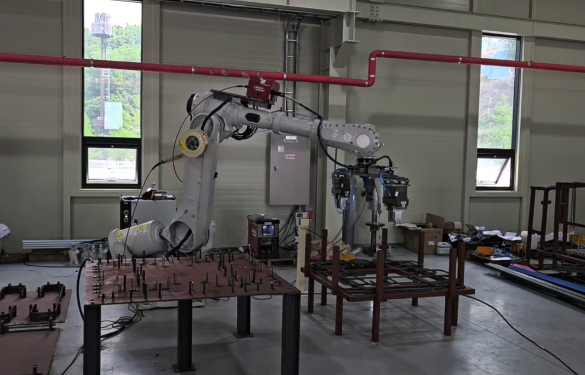

The pre-assembly welding process impacts not only

the structure's quality but also its safety.

With a 3D machine vision-based optimized welding robot

algorithm ANTON delivers the highest welding quality.

Safety incidents occur on construction sites every year,

yet training and protective measures alone are not enough

to resolve the issue.

The ANTON solution, powered by robot-based automation,

fundamentally prevents safety accidents.

Customer

System

.Rebar Loading Robot (ABB)

.Rebar Mounting System

.Hoop Rebar Supply Device

.Rebar Assembly Binding Device

.Automatic Tool Changer

.Hoop Rebar Magazine

.Customized Gripper

Customer

System

.Automatic Welding Robot (ABB)

.Automatic Welder (Fronius)

.Customized Gripper

*This is Robocon’s brand for rebar processing solutions.

ARON can replace 70% of the input manpower with robot-based

automation.

What is the productivity and utilization rate of your plant?

Process is one of the factors that have a huge impact on cost.

With ARON solution, operations run 24/7 continuously.

When processing rebar in Bar-in-Coil, the straightening largely

depends on the skill level of the operator.

The patented GSA* of ARON not only minimizes straightening time,

but also ensures reliable quality of rebar.

Safety accicents occur on the site every year, but safety training

and manual alone can't prevent them. ARON is an automated

production process using robots, which can fundamentally prevent

safety accidents.

ARON solution uses the RPM** program to manage all production

processes and data online including equipment control.

In addition, it is compatible with your existing MES so it can be

integrated into one system.

ARON can be manufactured in a portable container module.

In this way, it is possible to install and operate not only in factories

but also on construction sites in various environments.

Site

System

.Automatic Loading Robot (ABB)

.Automatic Tagging Machine

.Automatic Conveyor System

.Automatic Bending Machine (MEP Format16)

.Customized Gripper

Site

System

.Automatic Loading Robot (ABB)

.3-Way Automated Pallet Transfer System

.Automatic Bending Machine (MEP Format16)

.Customized Gripper

.20ft/40ft Container